For Rail Sections:

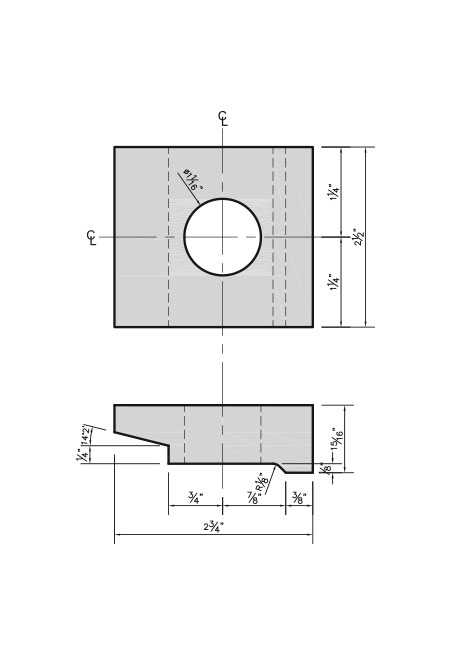

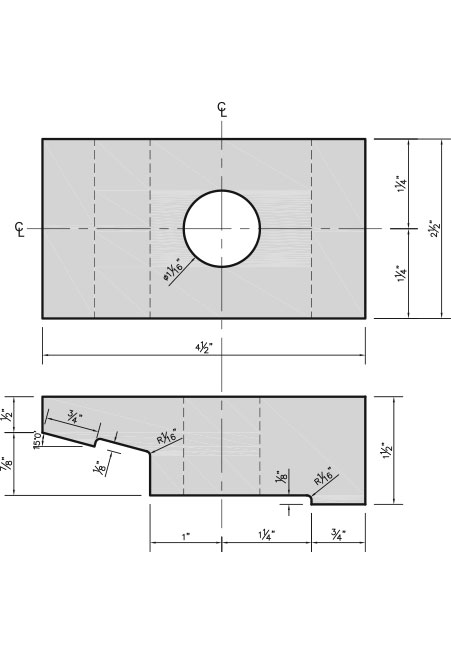

85# ASCE

115# AREA

132# AREA

104# Crane

105# Crane

#62 clip for weld-down or bolted applications

For Rail Sections:

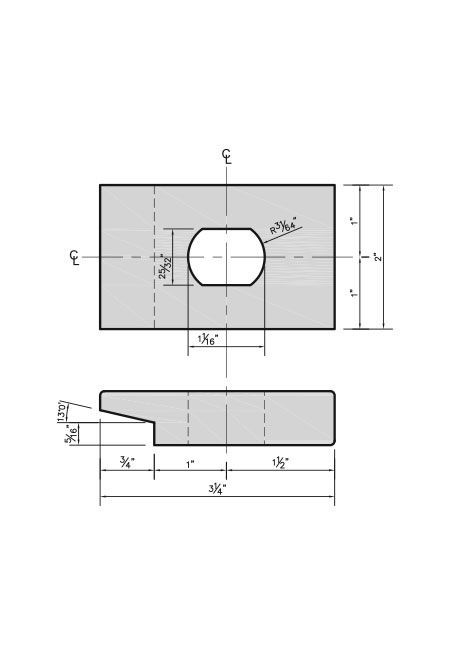

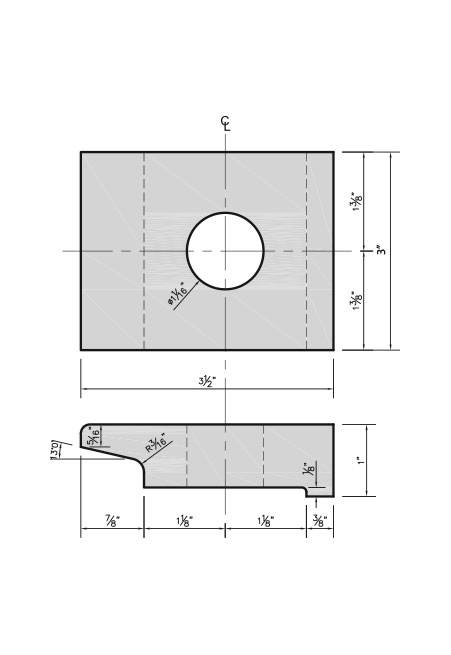

60# ASCE

80# ASCE

100# AREA

#106 clip for weld-down or bolted applications

For Rail Sections:

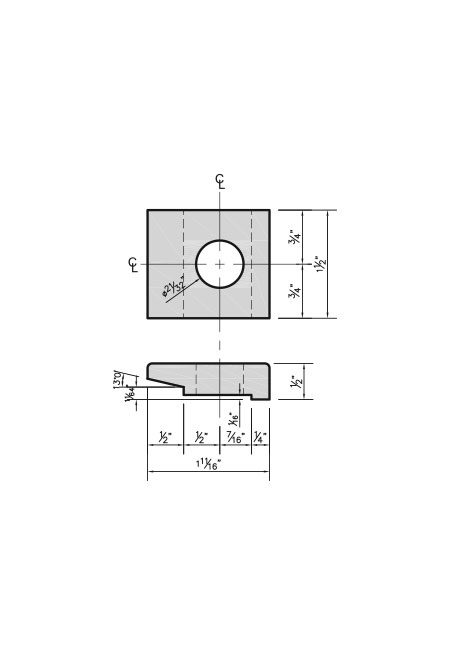

12# ASCE

20# ASCE

25# ASCE

30# ASCE

40# ASCE

#114 clip for weld-down or bolted applications

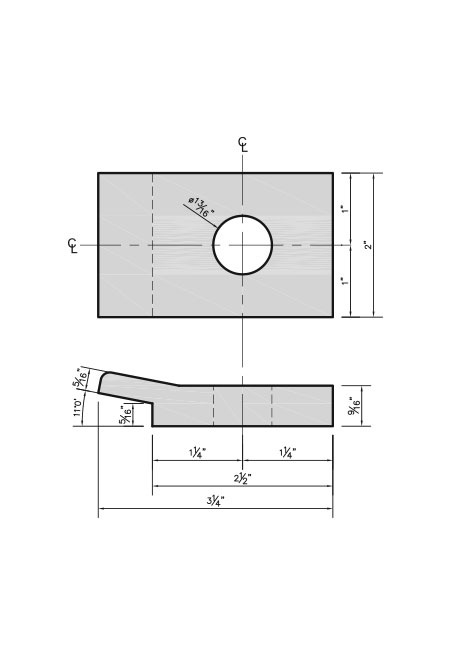

For Rail Sections: 40# ASCE

#120 clip for weld-down or bolted applications

For Rail Sections: 171# Crane Rail

#171 clip for weld-down or bolted applications

For Rail Sections: 175# Crane Rail

#175 clip for weld-down or bolted applications

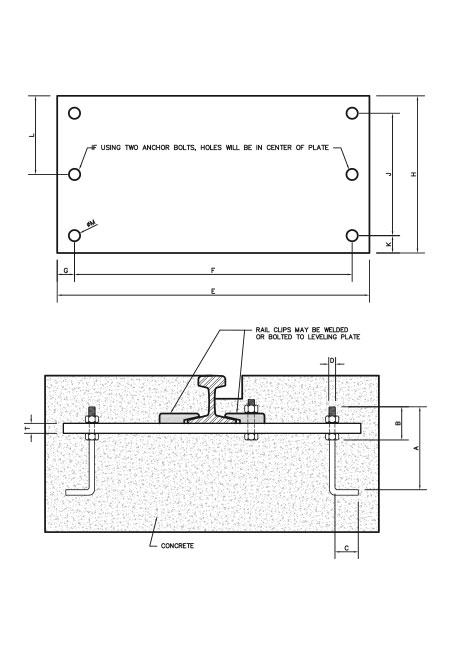

Speci cations required when ordering anchor bolts and leveling plate assemblies:

Anchor Bolts:

A. Length of anchor bolt

B. Length of thread

C. Length of leg

D. Diameter of bolt

Leveling Plate:

E. Width of plate

F. Center hole to center hole

G. Edge of plate to center hole

H. Height of plate

J. Center hole to center hole

K. Edge of plate to center hole

L. Edge of plate to mid center hole

M. Hole diameter

T. Plate Thickness

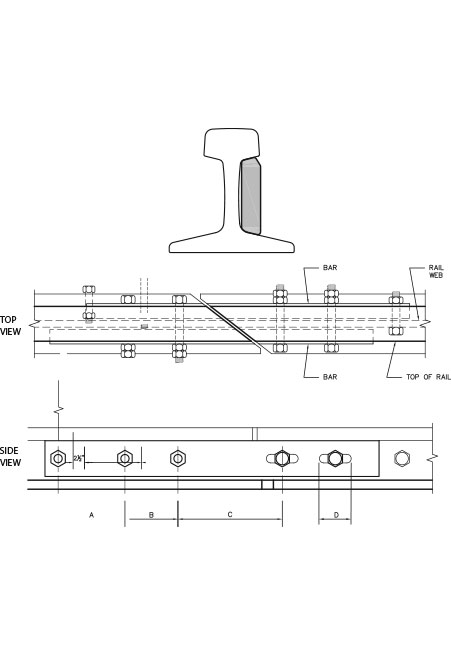

Specifi cations Required when ordering expansion joints

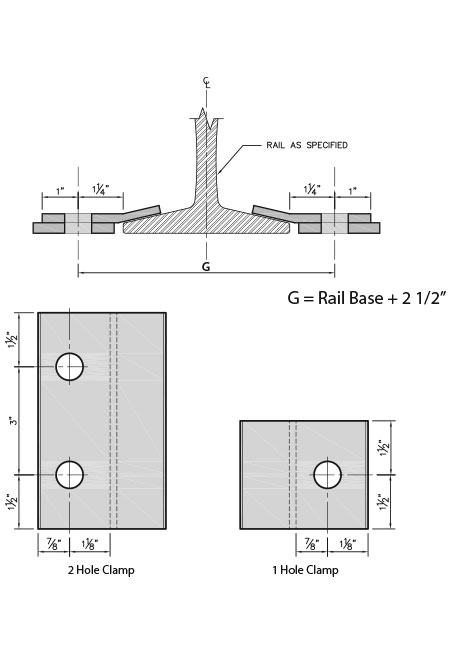

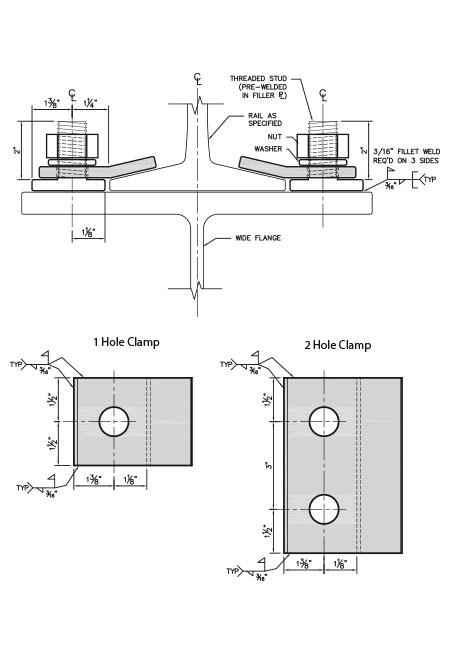

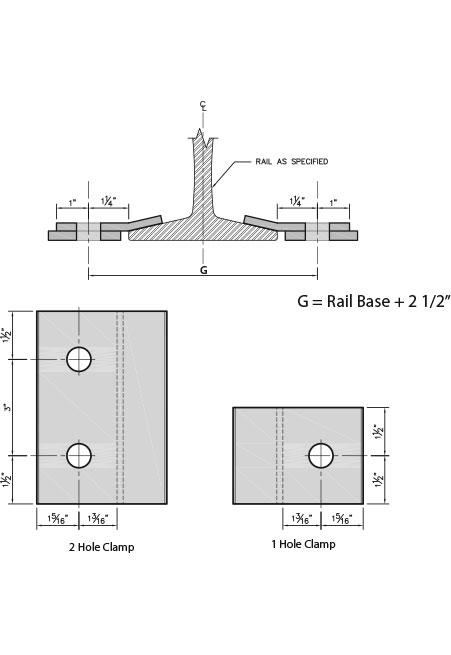

Normal spacing for 1 hole clamp and fi ller is one pair every 2 feet.

Normal spacing for 2 hole clamp and filler is one pair every 3 feet.

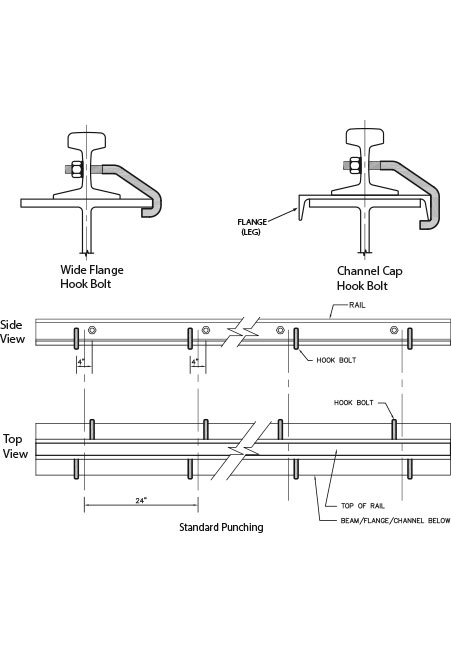

Speci fications required when ordering hook bolts:

| Rail Section and Size | Hook Bolt Diameter |

|---|---|

| 12# ASCE – 25# ASCE | 1/2" |

| 30# ASCE | 5/8” |

| 40# ASCE – 60# ASCE | 3/4" |

| 80# ASCE – 100# AREA | 7/8” |

| 104# Crane Rail – 175# Crane Rail | 1” |

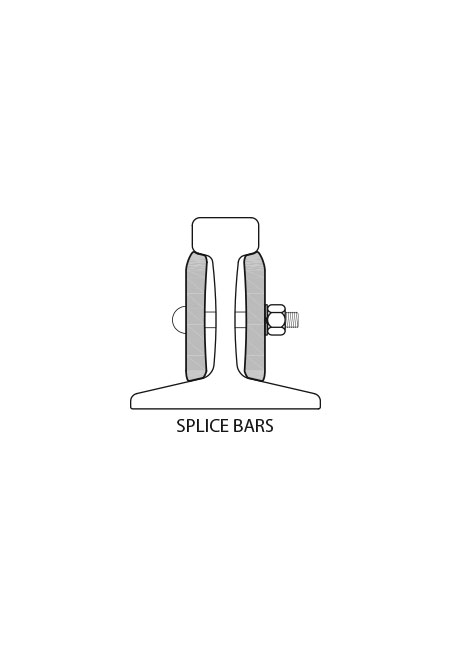

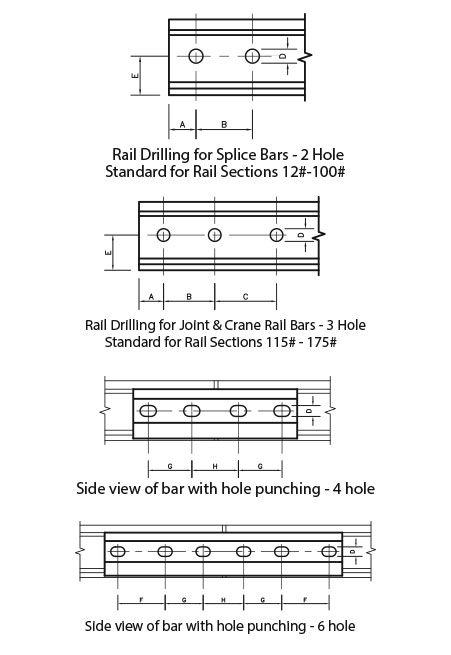

Splice bars standard for crane runways 12# ASCE - 85# ASCE.

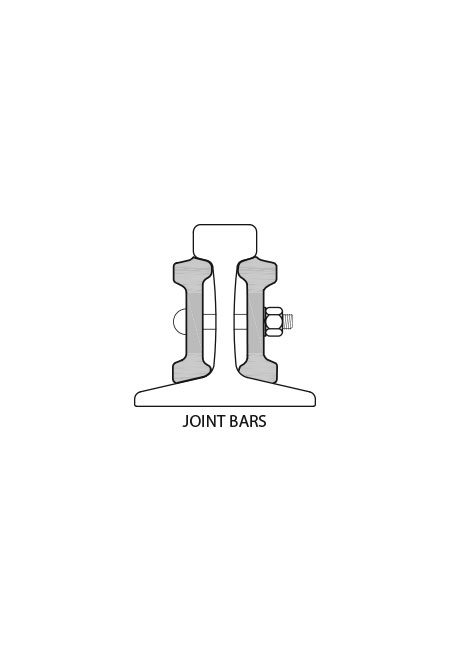

Joint bars standard for track material from 100# through 132#.

| Rail End Drilling | Bar Punching | |||||||

|---|---|---|---|---|---|---|---|---|

| Rail Section | A | B | C | D | E | F | G | H |

| 12# ASCE | 2" | 4" | NA | 9/16" | 57/64" | NA | 4" | 4" |

| 20# ASCE | 2" | 4" | NA | 9/16" | 1-11/64" | NA | 4" | 4" |

| 25# ASCE | 2" | 4" | NA | 9/16" | 1-15/64" | NA | 4" | 4" |

| 30# ASCE | 2" | 4" | NA | 11/16" | 1-25/64" | NA | 4" | 4" |

| 40# ASCE | 2 1/2" | 5" | NA | 15/16" | 1-9/16" | NA | 5" | 5" |

| 60# ASCE | 2 1/2" | 5" | NA | 15/16" | 1-29/32" | NA | 5" | 5" |

| 80# ASCE | 2 1/2" | 5" | NA | 1" | 2.38" | NA | 5" | 5" |

| 85# ASCE | 5" | 5" | NA | 1-1/8" | 2.47" | NA | 5" | 5" |

| 90# ARA-A | 2-11/16" | 5 1/2" | NA | 1-1/8" | 2.54" | NA | 5 1/2" | 5-3/8" |

| 100# AREA | 2-11/16" | 5 1/2" | NA | 1-1/8" | 2.75" | NA | 5 1/2" | 5-3/8" |

| 115# AREA | 3 1/2" | 6" | 6" | 1-1/8" | 2.98" | 6" | 6" | 7" |

| 132# AREA | 3 1/2" | 6" | 6" | 1-3/16" | 3.20" | 6" | 6" | 7" |

| 104# Crane | 4" | 5" | 6" | 1-1/16" | 2-7/16" | 6" | 5" | 8" |

| 105# Crane | 4" | 5" | 6" | 13/16" | 2-13/64" | 6" | 5" | 8" |

| 135# Crane | 4" | 5" | 6" | 1-3/16" | 2-15/32" | 6" | 5" | 8" |

| 171# Crane | 4" | 5" | 6" | 1-3/16" | 2-5/8" | 6" | 5" | 8" |

| 175# Crane | 4" | 5" | 6" | 1-3/16" | 2-21/32" | 6" | 5" | 8" |

Normal spacing for 1 hole clamp and ller is one pair every 2 feet.

Normal spacing for 2 hole clamp and ller is one pair every 3 feet.

Normal spacing for 1 hole clamp and ller is one pair every 2 feet.

Normal spacing for 2 hole clamp and ller is one pair every 3 feet.

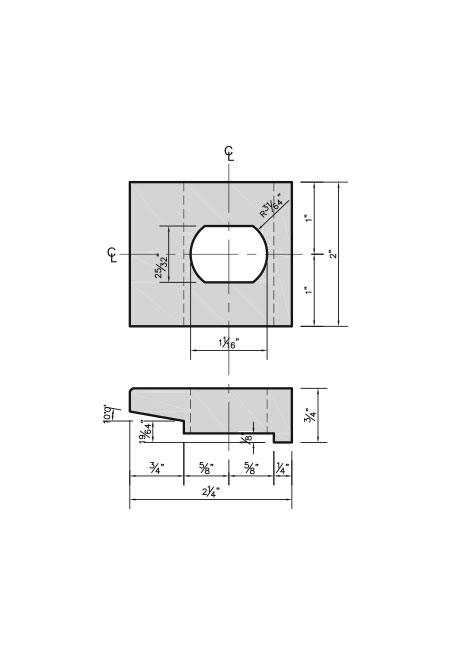

For Bolted Applications on 40# ASCE rail sections